Tips of welding Austenitic stainless steel

Austenitic stainless steel is the most widely used type of stainless steel, mainly Cr18-Ni8, Cr25-Ni20, Cr25-Ni35 type. The welding of austenitic stainless steel has obvious characteristics:

- Welding hot crack.

Austenitic stainless steel is easy to form a bulky columnar grain structure when the welding joint parts of high temperature and retention time is longer because of small thermal conductivity and large linear expansion coefficient. In the process of solidification, if the content sulphur, phosphorus, tin, antimony, niobium and other impurity element are higher, This leads to the formation of low melting point eutectic between grains. When the welded joint is subjected to high tensile stress, solidification cracks are easy to form in the weld seam and liquefaction cracks are easy to form in the heat-affected zone, which are welding thermal cracks. The most effective method to prevent hot crack is to reduce the impurity elements which are easy to produce low melting point eutectic in steel and welding materials and to make the Cr – Ni austenitic stainless steel contain 4% ~ 12% ferrite structure.

- Intergranular corrosion.

According to the theory of chromium depletion, the precipitation of chromium carbide on the intergranular surface, resulting in chromium depletion at the grain boundary, is the main reason for the intergranular corrosion. Therefore, choosing ultra-low carbon grades or welding materials containing stabilized elements such as niobium and titanium are the main measures to prevent intergranular corrosion.

- Stress corrosion cracking.

Stress corrosion cracking (SCC) is usually presented as a brittle failure, and the processing time of failure is short and the damage is serious. Welding residual stress is the main cause of stress corrosion cracking in austenitic stainless steel. The microstructure change of the welded joint or the stress concentration of local corrosive media are also the reasons.

- σ phase embrittlement of welded joints

σ phase is a kind of brittle intermetallic compound which mainly concentrated in the grain boundary of columnar grains. For Cr-Ni austenitic stainless steel, especially for Ni-Cr-Mo stainless steel, it is prone to the δ-σ phase transition and the change will be more obvious when the δ ferrite content in weld joints by more than 12%, making obvious embrittlement in the weld metal, that is why the delta ferrite quantity of hot wall hydrogenation reactor wall surfacing layer will be controlled in 3%~10%.

What welding material is suitable for 304 stainless steel welding?

Type 308 welding material is recommended when welding 304 stainless steel because the additional elements in 308 stainless steel can better stabilize the weld zone. 308L wires are also an acceptable option.

Low carbon stainless steel carbon content is less than 0.03%, while standard stainless steel can contain up to 0.08% carbon content. Manufacturers should give special consideration to the use of L-carbon welding materials because their low carbon content reduces the tendency for intergranular corrosion. Manufacturers of GMAW welding also use 3XXSi welds such as 308LSi or 316LSi because Si improves the wetting of welds. In cases where the weldment has a high hump or where the pool connection is poor at the toe of the fillet or lap weld, using an air-shielded wire containing Si can moisten the weld and increase the deposit rate. Type 347 welding materials with a small amount of Nb can be selected if carbide precipitation is considered.

How to weld stainless steel and carbon steel?

Some structural parts are welded to the surface of carbon steel with a corrosion-resistant layer to reduce costs. When welding carbon steel to alloy base metal, the use of higher alloy content welding material can balance the dilution rate in the weld. For example, when welding carbon steel and 304 or 316 stainless steel, as well as other dissimilar stainless steels, 309L wire or electrode is a suitable choice.

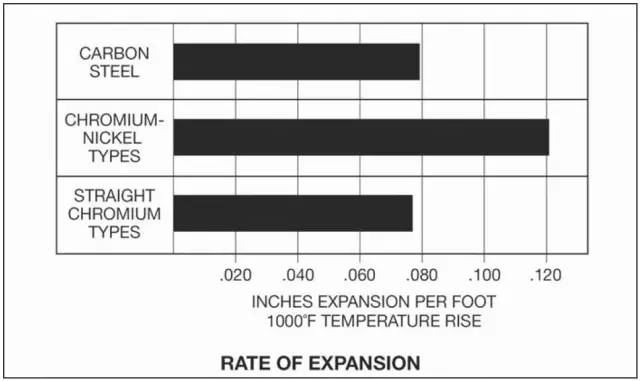

If you want to get a higher Cr content, use 312 welding material. It should be pointed out that the thermal expansion rate of austenitic stainless steel is 50% higher than that of carbon steel. When welding, the difference in thermal expansion rate will produce internal stress, which will lead to the crack. In this case, it is necessary to select the appropriate welding material or specify the appropriate welding process (Fig. 1). It shows when welding carbon steel and stainless steel, the warping deformation caused by different thermal expansion rates needs more compensation.

What is the proper pre-weld preparation?

Before welding, use chlorine-free solvent to remove grease, marks and dust to avoid the corrosion resistance of stainless steel base material from carbon steel. Some companies use separate storage of stainless steel and carbon steel to avoid cross-contamination. When special grinding wheels and brushes with stainless steel are used to clean the area around the bevels, it is sometimes necessary to perform a secondary cleaning of the joints. Because the electrode compensation operation of stainless steel welding is more difficult than that of carbon steel, the joint cleaning is important.

What is the correct post-weld treatment?

First of all, let’s recall that the reason why stainless steel does not rust is that Cr and O react on the surface of the material to generate a layer of the dense oxide layer, and play a protective role. Stainless steel rust is caused by the precipitation of carbide and heating during the welding process resulting in the formation of iron oxide on the welding surface. Perfected weldments in the welding state may also produce undercut in the rusted area at the boundary of the welding heat-affected zone within 24 hours. Therefore, in order to regenerate the new chromium oxide, stainless steel needs to be polished, pickled, sanded, or washed after welding.

How to control carbide precipitation in Austenitic stainless steel?

When the carbon content exceeds 0.02% at 800-1600℉, C diffuses to Austenitic grain boundaries and reacts with Cr at grain boundaries to form chromium carbides. If a large amount of Cr is cured by element C, the corrosion resistance of stainless steel will decrease, and intergranular corrosion will occur when exposed to a corrosive environment. The experimental results show that intergranular corrosion occurs in the heat-affected zone of welding in the water tank with corrosive media. Using low carbon or special alloy welding materials can reduce the tendency of carbide precipitation and enhance corrosion resistance. Nb and Ti can also be added to solidify C. Compared with Cr, elements Nb and Ti have a greater affinity with C. The grade347 welding material is designed for this purpose.

Why are stainless steel wires magnetic?

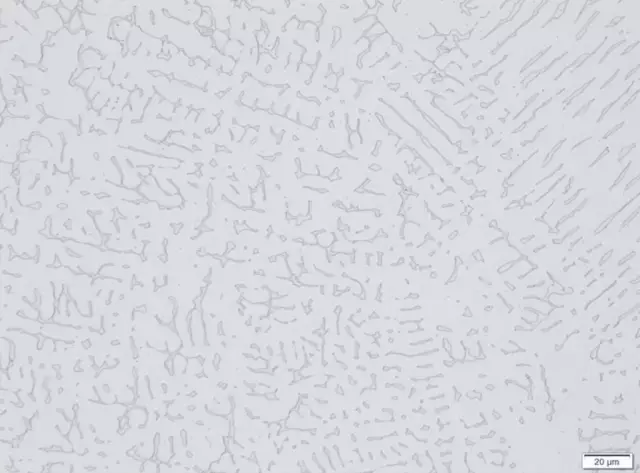

Stainless steels with full Austenitic structure are non-magnetic. However, the higher welding temperature makes the grains in the microstructure grow larger and the susceptibility to crack increases after welding. To reduce thermal crack sensitivity, the welding consumable manufacturer adds ferrite forming elements to the welding material (Fig. 2). The ferrite phase reduces the austenite grain size and increases the crack resistance. The following picture shows the ferrite phase (gray part) distributed on the austenite matrix in 309L welding material.

The magnet does not adhere firmly to the Austenitic weld metal, but a slight suction can be felt when thrown. This also leads some users to believe that the product is mislabeled or that the wrong solder material is used (especially when the label is removed from the package). The amount of ferrite in the welding material depends on the service temperature of the application. Excess ferrite, for example, reduces toughness at low temperatures. As a result, the ferrite quantity for grade 308 welding materials used in LNG pipelines is between 3 and 6, while the ferrite count for standard Type 308 welding materials is 8. In short, the welding materials may look similar, but even small differences in composition can sometimes make a big difference.