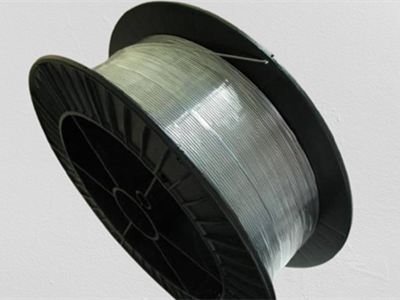

AWS 5.9 ER308LSi Welding Rod

Welder metals is one of the leading manufacturers, suppliers, exporters, stockiest of SS MIG/TIG welding consumables such as wires, rods and electrodes.

AWS A5.9 /ASME SFA 5.9 is the specification for welding consumables: wires, electrodes and rods for arc welding of stainless and heat-resisting steels. ER308LSi is the low carbon, high silicon, high tensile type of 308 stainless steel MIG wire and rods. The ultra-low carbon and increased silicon content assures better arc stability and excellent bead appearance with less porosity and spatter. It has excellent resistance to intergranular corrosion and cracks sensitivity, mainly used for welding 18Cr-8Ni stainless steel or where matching filler metals are required for 304L materials, also used for overlay welding as well as certain dissimilar welds of carbon steel to stainless steel in railway rolling stock pressure vessel, chemical machinery, muffler welding.

ER308LSi Welding Wire/Rod Specifications

| Weld Process | MIG, TIG(GTAW), SAW |

| MIG coils wires | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.6mm, 2.0mm –15kg/piece |

| TIG straight rods | 1.2mm, 1.6mm, 2.0mm, 2.5mm, 3.2mm, 4.0mm–5kg/piece |

| SAW spools | 2.0mm, 2.4mm, 3.0mm, 4.0mm–25kg/piece |

| Surface treatment: | Bright finish, Semi-bright finish |

ER308LSi Chemical Composition

| Grade | C | Si | Mn | S | P | Ni | Cr | Mo |

| 308LSi | 0.03 | 0.65-1.0 | 1.0-2.5 | 0.03 | 0.03 | 9.0-11.0 | 19.5-22.0 | 0.75 |

ER308LSi Mechanical Property

| Tensile strength | Yield strength | Elongation In 2” |

| 158,000 Psi | 171,000 Psi | 39% |

The stainless steel rods ER308LSi supplied by us are in strict accordance with AWS A5.9 and other equivalent standards. We provide not only high-quality products but also have access to a vast stock of aluminum, titanium, and other alloys as per the specifications of American, European and Chinese specifications. We are here and our experienced technical team is waiting to help you with your inquiry, so contact us now!