What’s K-TIG welding?

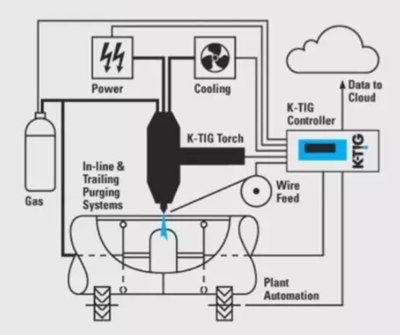

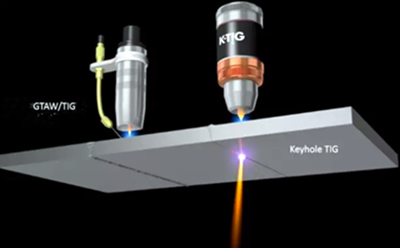

Keyhole TIG welding, K-TIG for Short, is a new high current TIG welding technology developed by Australia CSIRO company in 2000. K-TIG welding technology is a high-speed one-side full penetration weld process, which requires no wire, no groove or no professional operators, but can weld metal up to 16mm thick and 100 times faster than conventional TIG welding.

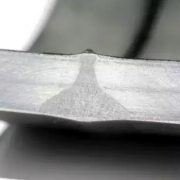

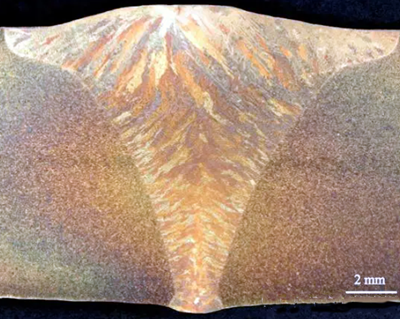

K-TIG welding is based on the traditional TIG welding through the large current (> 300A) to form a large arc pressure and weld pool liquid metal surface tension to achieve a relative balance, forming a hole to achieve deep welding. Stable welding process, beautiful welding forming, weld microstructure and mechanical properties are better than TIG welding, is a high efficiency, high speed, low-cost welding method. The tungsten electrode diameter is greater than 6mm (commonly used diameter is 6.3-6.5mm, the Angle of the end is 60o), the welding current is up to 600~650A, the arc voltage is 16~20V, under the action of such a high specification parameters, the electromagnetic shrinkage of the arc is greatly improved, showing the arc straightness, arc force and penetration ability are significantly enhanced.

In welding, the arc “sinks” deeply into the base metal, forcing the molten metal around the molten pool to form keyholes. If the arc pressure, the reaction force of metal vapor on the sidewall of the keyhole, the surface tension of the liquid metal and the pressure inside the liquid metal reach a dynamic balance, the keyhole will exist stably. As the arc progresses, the pool metal is fused behind the arc and cooled to form a weld, similar to the plasma “keyhole” welding method.

| No. | Item | SAW | TIG | PLASMA | A-TIG |

| 1 | One Side Welding Both Sides Formation | No | Yes | Yes | Yes |

| 2 | Maximum depth of fusion | 20mm | 3mm | 10mm | 16mm |

| 3 | Medium and thick plate groove | No | Yes | No | No |

| 4 | Medium and thick plate once forming | No | No | Yes | Yes |

| 5 | Apperance quality | Good | Good | Not good | Good |

| 6 | Welding alignment clearance | ≤2 | ≤2 | ≤0.5 | ≤2 |

| 7 | Welding Consumables | Need welding wire and flux | Need more wires | Need plasma gas | Need less wires |

| 8 | Maximum welding speed | 400mm/min | 200mm/min | 500mm/min | 1000mm/min |

| 9 | Arc initiation/closure defects | Yes | No | Yes | No |

| 10 | Rated load ratio | 60% | 60% | 60% | 100% |

The features of K-TIG welding

- Automatic welding, simple operation, no welding wire filling, the whole process is one-way full penetration welding.

- High efficiency, low energy consumption, fast welding speed, the speed is more than 5-10 times of ordinary TIG/GTAW. It allows weld defects to form highly stable, self-correcting full penetration weld holes in a variety of special metals. The clearance of welding parts can be up to 2 mm.

- The medium thickness metal plate can realize single-sided welding and double-sided forming without groove opening, with beautiful welding seam, small deformation and no root cleaning on the back.

- It can weld carbon alloy steel, stainless steel, titanium alloy, nickel base alloy, cobalt alloy and zirconium materials, especially for large diameter Austenitic stainless steel. K-TIG deep penetration argon arc welding in 16mm titanium, 14mm zirconium, 13mm Austenitic stainless steel, Hastelloy, nickel-chromium and various nickel-cobalt alloys and 9mm conductive materials (such as Ferritic steel and carbon steel) to achieve a single side welding double side forming. When the welding speed is 250-300mm/min, it can weld through the stainless steel below 14mm at a time.