Flux-cored welding wire VS Solid welding wire

Welding wire can be divided into solid cored wire and flux-cored wire according to its structure. Most solid core wire is made of cold drawn steel wire, mainly include submerged arc welding wire (carbon steel, low alloy steel welding wire, stainless steel wire), gas shielded arc welding wire( TIG welding wire, MIG and MAG welding wire, CO2 welding wire), electro slag welding wire, surfacing welding wire, copper wire, nickel welding wire, aluminum welding wire, iron wire, etc. The flux-cored wire is a coating solid metal wire made of flux powder wrapped in the outer layer, that’s mainly iron powder, TiO2, SiO2, BaF2, Fe-Mn, Fe-Si, Al, Mg, etc, playing a series of beneficial parts in the welding process, such as protecting droplet and pool from oxidation, nitriding, assisting weld forming, stabilizing arc, deoxidation, desulfurization and alloying. Today here we will analyze their main differences in this article:

Deposition rate

Deposition speed refers to the amount of metal deposited on the weldment per unit time in the process of fusion welding. Flux-cored wires fuse faster than solid electrodes because they allow a larger welding current to be used (shown below). Compared with solid cored wire, because its current is concentrated on the outer steel surface, offering a large current density and larger resistance heat generated; In addition, the flux-cored wire has a small splash, and its molten metal can be more efficient into the pool.

| Welding wire types | Welding wire diameter /mm | Best welding current range/A | Allowable welding current range/A |

| Solid welding wire | 0.6 | 40~90 | 30~180 |

| 0.8 | 50~120 | 40~200 | |

| 0.9 | 60~150 | 50~250 | |

| 1.0 | 70~180 | 60~300 | |

| 1.2 | 80~350 | 70~400 | |

| 1.6 | 300~500 | 150~600 | |

| Flux-cored welding wires | 1.2 | 80~300 | 70~350 |

| 1.6 | 200~450 | 150~500 | |

| 2.4 | 150~350 | 120~400 | |

| 3.2 | 200~500 | 150~600 |

Welding efficiency

Flux-cored wire can be continuously automated and semi-automated production, which greatly saves the time of changing electrode, arc starting and arc closing and other auxiliary processes. Compared with solid wire, flux-cored wire welding spatter less, weld forming, reduce the time of cleaning spatter and repairing weld surface, not easy to plug the nozzle, which is more suitable for robot welding compared with CO2 solid cored wire.

The cost

Compared with the manual electrodes and solid wire, flux-cored wire is expensive. However, the flux-cored wire can greatly shorten the production cycle and guarantee the weld quality, with a comprehensive cost economy, which is much lower than electrode arc welding, and about the same as CO2 solid cored wire.

Use

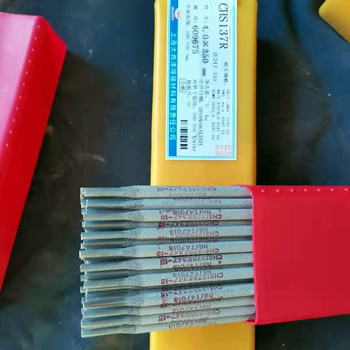

The flux-cored wire is mainly used for flat welding and fillet welding in construction machinery, heavy machinery, steel frame, bridge, etc. Solid welding wire is widely used as filler metal or conductive metal wire welding material. It is used as filler metal in gas welding and tungsten gas shielded arc welding. It is both a filler metal and a conductive electrode in submerged arc welding, electroslag welding and other fusion gas shielded arc welding.

Moisture resistance

ISO 3834-2:2005 Quality requirements for fusion welding of metallic materials state: “The manufacturer shall establish and implement procedures for the storage, storage, identification and use of welded materials to avoid moisture, oxidation and damage, in accordance with the recommendations of the supplier.”

Flux-cored wire has a continuous gap on the side of its steel layer due to the constraints of its manufacturing form, it cannot be exposed to the air for too long after opening the package, in order to prevent excessive moisture absorption and affect the welding quality. For flux-cored wire and other welding materials with powder layer, manufacturers can usually specify the basic requirements for drying, storage and drying. There are no requirements for the storage of solid cored wire, generally does not need to be dried before use, but this does not mean that solid cored wire has no requirements, consult the welding wire manufacturer for details.