Titanium Welding Wire/Rod

Titanium has active chemical characteristics, it is easy to be polluted by air, water, oil, oxide film, also absorb the impurities like oxygen, nitrogen, hydrogen, carbon and others, which reduced the toughness and plasticity of the welding joint and cause pores in the melting state, even if the solid high temperature up to 400℃. In addition, titanium and titanium alloys have poor weldability due to their high melting point, large heat capacity, large electrical resistance and poor thermal conductivity. Usually be conducted by the small current, high speed plasma arc welding (PAW), laser -MIG composite welding and TIG welding. Weldermetals is a leading platform of Titanium and its alloy welding wires, rods for MIG, TIG(GTAW) welding. Our wires strictly conform to the standards and manufactured as per the specifications of the AWS, ISO, BS, EN and GB.

TITANIUM TIG WELDING WIRES

TIG(GTAW) is the commonly used welding method for titanium and titanium alloy, often used for welding workpieces within 3mm thickness. The filling wire of titanium and titanium alloy should be selected according to the base metal. Generally, the metal composition is the same as the base metal. Sometimes, the welding wire with slightly lower alloy and strength than the base metal can be selected in order to improve the plasticity of the weld joints, The size of the wire should be selected according to the thickness of the base metal. Commonly used materials include ERTI-1, ERTi-2, ERTi-5, ERTi-23 in accordance with AWS A5.16.

Titanium TIG Wires Specification

| Grades | ERTi-1, ERTi-2, ERTi-3, ERTi-4, ERTi-5, ERTi-23 |

| Specifications: | AWS A5.16, ASME SFA 5.16, ASTM B348, ASTM F67, ASTM F136, ISO 5832/2, ISO 5832/3, ISO 5832/11, AMS 4928, GB/T 3623 |

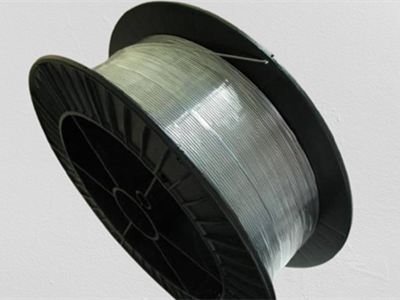

| Size | Spools/Coil: 1.0、1.2、1.6mm(Wire reel)

Rolled wires: 1.2、1.6、2.0、2.4、3.0、4.0、5.0mm Straight wires: 1.2、1.6、2.0、2.4、3.0、4.0、5.0、6.0mm; 5kg |

| Surface treatment: | Bright finish |

| Packaging | Cardboard boxes or customized Packaging as per requirements. |